Frequently Asked Questions

Q: What should I do if my pizzelles are sticking to the iron?

To make perfect pizzelles without them sticking, always start by fully preheating your iron—this takes approximately 15 minutes. Once the iron is hot, it’s important to properly season it before adding any dough. Use a thin layer of Crisco Shortening on both the top and bottom grids, as it handles high heat well. If you prefer, non-stick spray, canola oil, or olive oil can also work. After seasoning, place the dough on the grids and close the iron, cooking each pizzelle for about 35 to 55 seconds depending on how crisp or soft you like them. If your pizzelles are cooking within that time frame but still sticking, the issue is most likely with the dough consistency.

In that case, try adjusting your dough by gradually adding more flour until it

no longer clings to the iron.

Quick Steps:

· Preheat the pizzelle iron completely (about 15 minutes).

· Apply a thin layer of Crisco Shortening (or non-stick spray/oil) to both grids.

· Place dough on the iron and close it.

· Cook for 35–55 seconds, based on desired doneness.

· If pizzelles are cooking within that time but stick, adjust the dough.

· Gradually add more flour until sticking stops.

Q: What are the main differences between Model #1000 and Model #7500?

The distinctions between our Pizzelle Iron models are as follows:

- Model #1000: This is our original Pizzelle Iron, in production for over 65 years. It creates pizzelles that are 0.26 inches thick and measure 4.75 inches in diameter.

- Model #7500: Released as part of our 75th Anniversary celebration, the Model #7500 features a unique design. It produces thinner pizzelles at 0.18 inches thick, while maintaining the same 4.75-inch diameter.

Quick Comparison:

· Model #1000 – 0.26" thick pizzelles, 4.75" diameter

· Model #7500 – 0.18" thick pizzelles, 4.75" diameter

· Model #1000 – Classic design in use for 65+ years

· Model #7500 – Special edition for the 75th Anniversary

Q: What is the recommended method for cleaning my Palmer Pizzelle/Belgium Cookie Iron?

Cleaning your Palmer Pizzelle or Belgium Cookie Iron is easy and helps maintain its performance. Here’s how to clean it properly, whether for regular maintenance or deeper care.

Cleaning Steps:

· Regular Cleaning – Wipe the iron with a damp cloth to remove surface residue.

· Deep Cleaning – Use food-safe ingredients for a thorough clean:

- Sprinkle baking soda over the grids.

- Add a small amount of white vinegar to create bubbling action.

- Gently scrub with a toothbrush to lift stubborn debris.

- Carefully rinse, avoiding any liquid contact with electrical components.

· Precautions – Never allow liquid to seep under the top or bottom lids, as this can cause electric damage.

· Maintenance Note – A well-used iron may not look brand new. Embrace its seasoned appearance as a sign of quality and durability.

Q: Does C. Palmer Mfg. Inc. offer shipping outside the Continental USA?

Yes, we do offer shipping beyond the Continental United States. To receive an accurate quote for your location, please call us directly at (724) 872-8200.

Important Shipping Info:

· Shipping fees are based on current USPS rates.

· Typical cost to ship an electric iron outside the Continental U.S. often exceeds $65.00.

· Contacting us directly ensures you get the most accurate and up-to-date shipping information.

About Us

The C. Palmer Mfg. Family

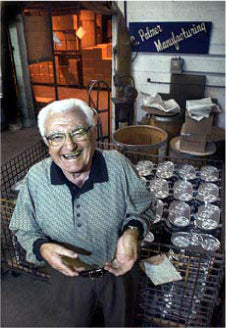

Carmen Palmieri founded our company in 1943 in his basement with no money and a strong desire to work. The first aluminum castings he made were tiny Italian cookie irons. After filling an order for sinker molds requested by one of his customers, he decided to create an entire line of molds, branded with his name. Because it was difficult to sell products under a very Italian sounding name at that time, he Americanized it to be C. Palmer Manufacturing, Inc.

From a basement to modern manufacturing plant

As the business continued to grow, the product line expanded, too. By the late fifties, his basement was too small for the operations, so Carmen and his first son, John, built the company's first plant. John was fresh out of the Navy and anxious to help his father. He had worked in electronics during his time in the Navy, and he had several new, innovative ideas for products, as well as plans for how they could automate the production. The company introduced the first electric Pizzelle Iron and the Palmer Sandwich Toaster.

Sales were booming, and it did not take long to outgrow the existing plant. In 1964 they purchased land and built a new plant with more than enough room, or so they thought. John designed and installed a fully automated sand casting system. Many companies were quite impressed with it, and one national electronics manufacturer sent their engineers to the plant to see how it was set up. They were amazed that such a small company could have so much automation with limited resources, and they asked to use some of the ideas that John had implemented. He agreed.

C. Palmer Manufacturing bought their first aluminum die cast machine in 1976, which boosted the quality of the products and reduced the need for secondary operations. By the end of the 70s, a Tool and Die department was added which allowed us to grow substantially. We could now build our customers' dies at a minimal charge, saving them thousands of dollars and providing us assurance that the dies were properly constructed.

Transition to the next generation

In 1979 Carmen "retired", but he continued to come to work, keeping his 7:00 am to 3:30 pm regiment for thirty-two more years, until he was 96 years old.

In 1980 it was necessary to expand with an addition and again two years later. John's first son, Philip, joined the company in 1984 and introduced computerization to the production process. Sand casting was phased out and converted to die castings.

In the late 90s, the company was still growing rapidly, and two of our largest customers projected increases of 40% to 100% in their purchases for the following season. Again, it necessary to expand, and C. Palmer Manufacturing opened their die casting division, C. Palmer Die-Casting, Inc. in Oakland, Maryland. Darcy, John's daughter and Carmen's granddaughter started working at C. Palmer Mfg in 1996 and took over running the company when John retired in 2003. Soon after they began offering their products online.

Loss and growth

On Friday, March 11, 2011 C. Palmer Mfg. lost their founder. Carmen Palmieri, 96, of West Newton. He died in Excela Health Westmoreland Hospital, Greensburg. He was born on June 12, 1914 in Lettopalena, Italy, and his parents were John and Assunta (Tranchni) Palmieri.

It was a sad day for all of C. Palmer Mfg. His friends and family still miss his smile and his ability to make you laugh with his jokes. He was a hard worker and dedicated to his business. The employees miss having him around, too, giving advice and always providing a helping hand.

Despite the loss, the company continued to thrive and grow throughout the 2010s. We passed our 75 year anniversary in 2018, designed a new pizzelle iron, and we are excited for what the future has in store for C. Palmer Mfg.!